From prototype to production we’re here to guide you through the Plastic Injection Moulding process.

“S.B. Weston have been designing & manufacturing plastic products in south-west London since 1948. We have a suite of new plastic injection moulding machines and decades of moulding experience ready to apply to your project.”

Reid Weston - Company Director

Our Services.

Injection Moulding

We supply injection moulded parts in a diverse range of materials up to 1.2kg in weight from our suite of Hiatian injection moulding machines which enable us to turn custom moulding jobs around quickly and cost efficiently. Read more about our Injection Moulding services.

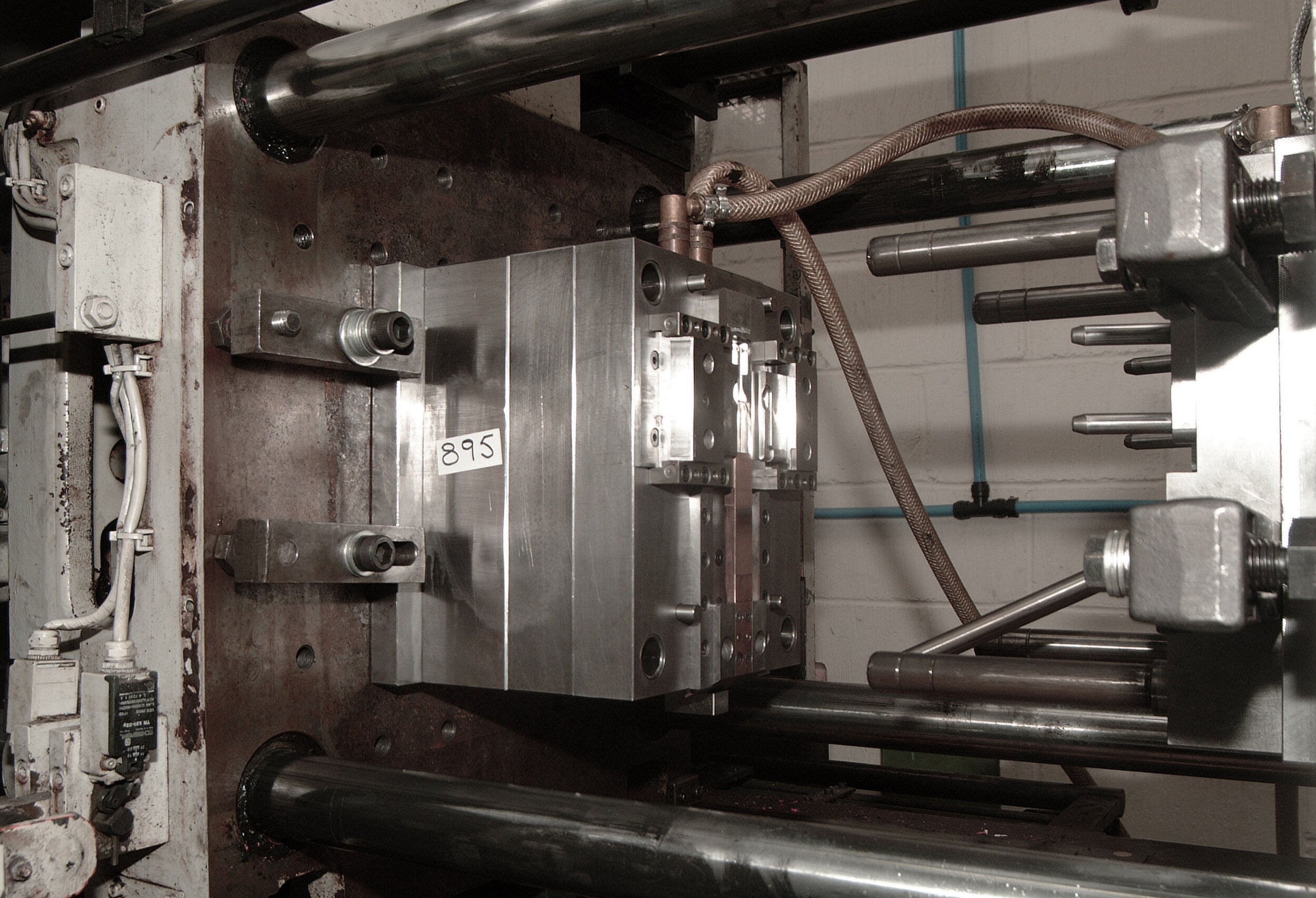

Mould Design & Tooling

We supply quality, precision engineered plastic injection mould tools. Whether a low cost, low run prototype mould or a high volume tool requiring robotic handling, we have the design and build experience required. Read more about our Mould Tooling services.

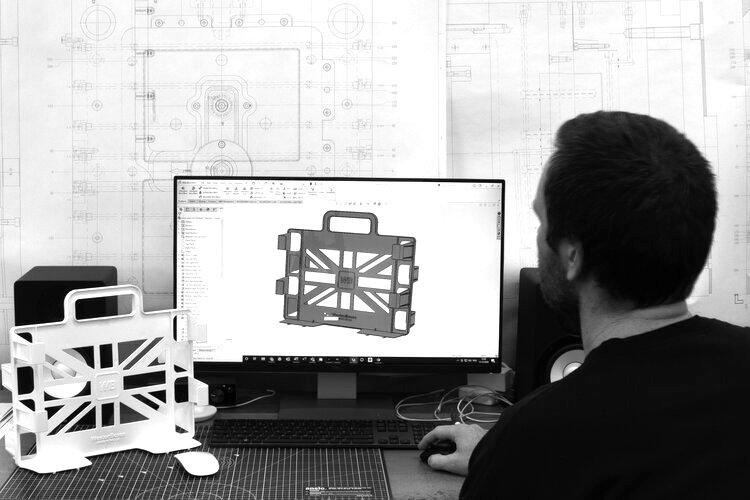

CAD Component Design

We offer CAD component design services using SolidWorks CAD software to create 3D models, 2D dimensioned drawings and files ready for 3D printing or injection mould tooling. Read more about our CAD Drawing service.

Finishing & Packing

We offer CAD component design services using SolidWorks CAD software to create 3D models, 2D dimensioned drawings and files ready for 3D printing or injection mould tooling. Read more about our CAD Drawing service.

3D Printing & Prototypes

We can supply 3D printed SLA (Stereolithographic), SLS (Selective Laser Sintering) and FDM (Fused Deposition Modelling) rapid prototype models on short turnaround times. Read more about our 3D Printing & Prototyping services.

Project Management

We can supply 3D printed SLA (Stereolithographic), SLS (Selective Laser Sintering) and FDM (Fused Deposition Modelling) rapid prototype models on short turnaround times. Read more about our 3D Printing & Prototyping services.